We knew it was coming, of course. But finally the moment has arrived: the W12, Bentley’s ‘iconic’ power source for over 20 years, has officially ended production. It is encouraging at least that the firm chose to mark the occasion in the most English way possible (they had a nice lunch and took some vaguely awkward pictures) but it is still a sad day for anyone with a lasting affection for pleasingly large, weighty petrol engines. Which is surely all of us in the context of large and weighty Bentley products.

That the W12’s distant origins were not very much not British is a subject left mostly unsaid in the manufacturer’s press release – and on the basis that Bentley has been exclusively responsible for hand-building (and continually updating) the engine since at least 2014, it would indeed be churlish to deny the brand spiritual ownership. Certainly, its relatively short-term appearance in other VW Group products is mostly forgotten about now; it is unquestionably the Continental GT that will be forever synonymous with 6.0-litre twin-turbocharged unit.

“The W12 has played such an important role in the history of Bentley that it was only right for us to celebrate the engine’s retirement with those linked to this powerplant. The engine’s introduction helped change the face of the company almost overnight and so will go down in history as a true game changer and we should feel very proud to have designed, developed and manufactured such an icon in Britain for such a long period of time,” said Andreas Lehe, Member of the Board for Manufacturing at Bentley Motors.

Though one could argue that the W12 remains firmly in the shadow of the L-series V8 – an engine that Bentley built in one format or another for six decades – its success and contribution to the firm is hardly up for debate. Nor is its performance: thanks to turbocharging, the engine arrived in 2003 with 560hp – a prodigious amount for the time, and crucial to the Continental GT’s original sales performance. Two decades later, it finished up in the limited edition and frighteningly expensive Batur with 740hp.

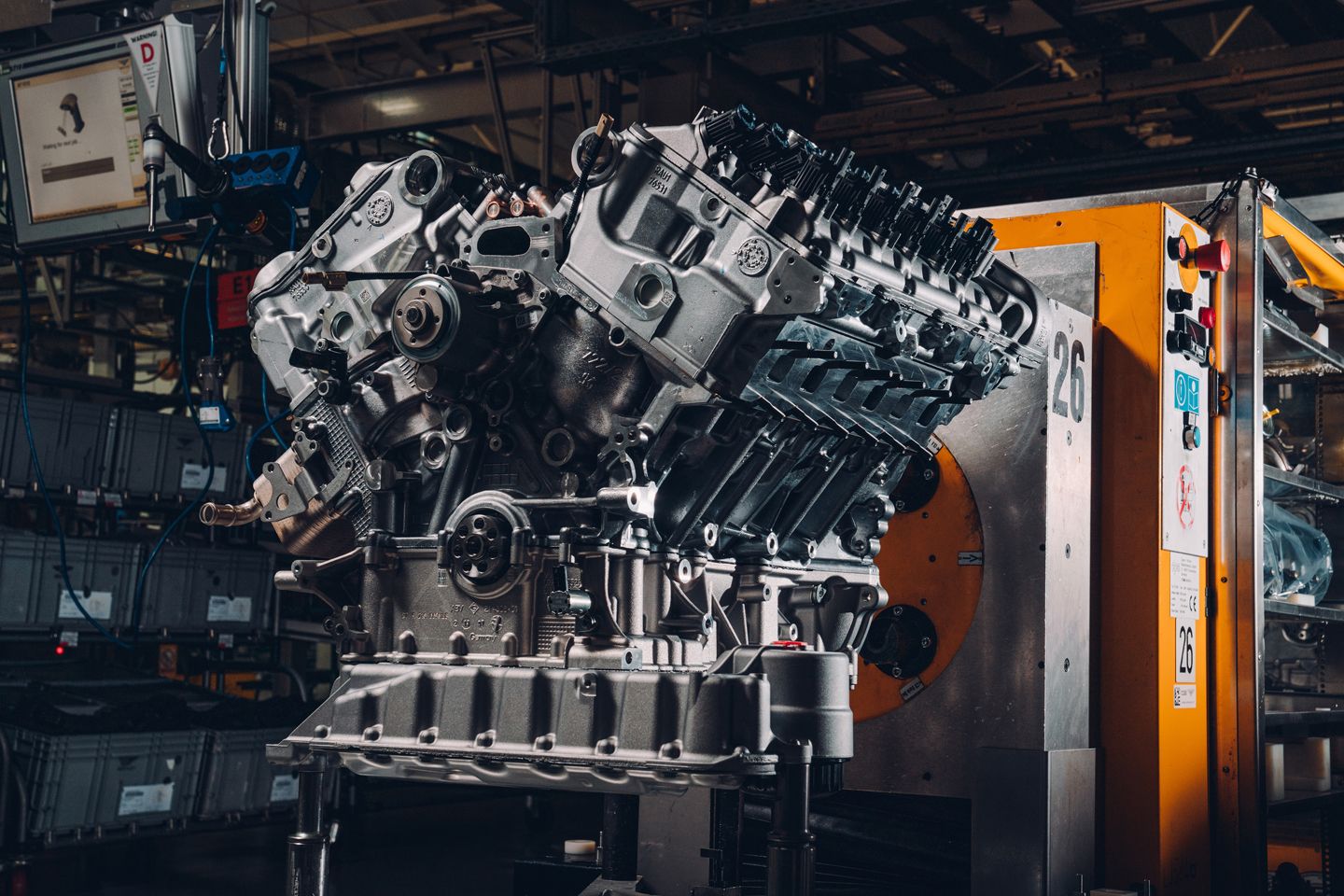

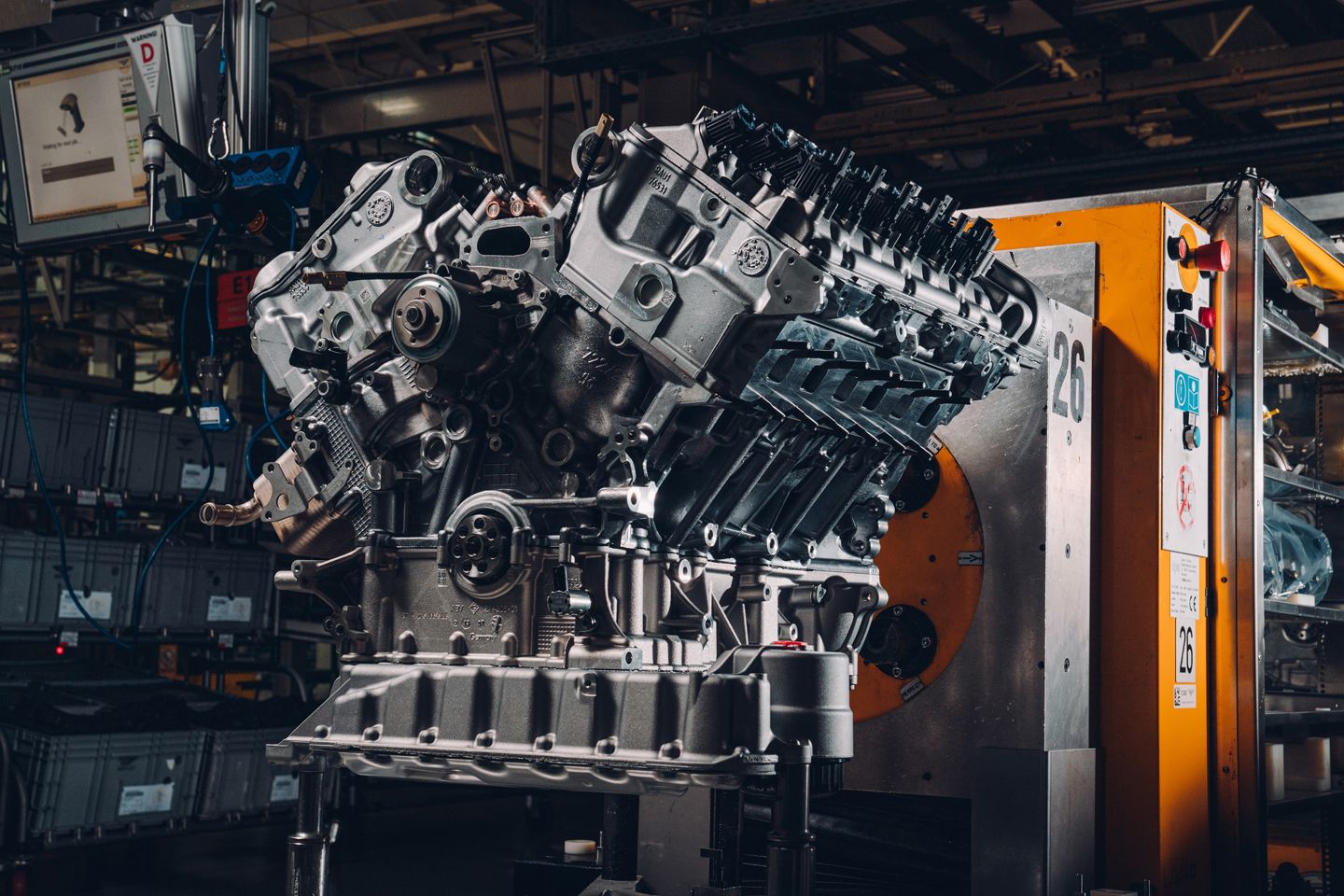

No less impressive is the fact that while it managed to coax a 34 per cent increase in power (and 54 per cent in torque), its maker also achieved a 25 per cent reduction in CO2 emissions. This from an engine famous for its complexity: it is said to have featured 2,600 components and took around seven hours to build. That Bentley reckons 100,000 examples are still on the road is a testament to its testing regime and the (generally speaking) bullet-proof nature of the unit itself. Assuming you don’t need to remove it to fix something, well-kept W12s have a sterling reputation for longevity.

This is good news because once the final examples of Bentayga, GT and Flying Spur are ushered from the factory gates, there will be no more. On the basis that demand for battery-powered luxury cars has slackened (to say the least) it is conceivable that Bentley might come to regret its decision to end production completely – but with its all-new 782hp Ultra High Performance Hybrid V8 powertrain waiting in the wings, the brand seems confident enough that it has found a good time to close the book on its last-ever 12-cylinder engine.